- New

- All TZ Pro software (4 displays via HDMI)

- Intel Core i7 1255U (1.7 - 4.7 Ghz) 12th Gen

- DDR4 32 GB

- 500 GB SSD

- W10 pro

- 9 to 36 V

- Power consumption: 7 to 60 W

- 230x200x68 mm (L x W x H)

- 2.64 kg

- 2-year warranty

CATALOG AND PRICE LIST

CATALOG AND PRICE LIST

ENERGY

ENERGY

COMPUTER SCIENCE

COMPUTER SCIENCE

INSTALLERS

INSTALLERS

BLOG CONSEIL

BLOG CONSEIL

New products

The alternator charger is characterized by its easy installation as it simply replaces the existing distributor. It is the ideal solution for fast and complete recharging of service batteries from the alternator and one of the first options to consider for improving autonomy.

It represents an interesting alternative to the installation of a generator insofar as the alternators represent an important source of energy on board (most of the current engines have alternators whose power is higher than 100A). By optimizing the recharge from the engine (adjustment of the charge cycle), the batteries can be recharged quickly.

| Function | Fast (2 to 5 times faster) and completecharging of the service batteries from the alternator and charge distributor for the engine battery |

|---|---|

| Connection | Without disassembling the alternator (connection similar to that of a distributor) |

| Compatible alternators | All types of 12V alternators up to 300A. Several alternators can be connected to the alternator charger as long as their combined power does not exceed 300A. |

| Compatibility | Compatible with all types of batteries including lithium (9 cycles available) and alternators. |

| Charging cycle applied | IUoU three-phase charge cycle with temperature compensation |

| Charging current | 300A maximum (depends on alternator power) |

| Number of outputs | One service battery output (three-phase cycle) One motor battery output (voltage regulation) The number of service or motor outputs can be increased by using a prosplit R cascade splitter |

| Control and parameterization | Information available by LED: voltage control, battery type set, alarms. |

| Temperature sensor | Two probes included (one for the service park to adjust the charging voltage and one to ensure the protection of the alternator). |

| Remote control panel | The optional remote control panel, allows to control all the parameters of the charge cycle and to stop or restart the boost function (delivered with 10 m cable) |

| Weight | 5.0 Kg |

| Dimensions | 370*288*70 mm |

The range of alternator chargers extends in 12 V from 80 A to 400 A and in 24 V from 80 A to 200 A. You will find the whole range in the product sheet available under this link.

The charging performances obtained from the alternator become equivalent to those of the most sophisticated shore power chargers (three-phase charging cycle (boost, absorption, floating) by software control with temperature compensation of the battery park). This product is also called booster because it allows to recharge a battery pack 3 to 5 times faster than with a system based on a diode charge distributor (twice as fast as a system where the battery is connected directly to the alternator).

As an option, a remote control panel can be used which provides all the information corresponding to the charge cycle (voltage, temperature, status of the cycle) but also allows the boost function to be activated or deactivated. This control panel is available under this link

The results obtained with the alternator charger are equivalent to those of the alternator regulator, but this product differs in that it is easy to install (no need to disassemble the alternator).

|

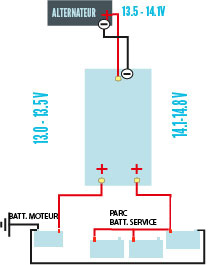

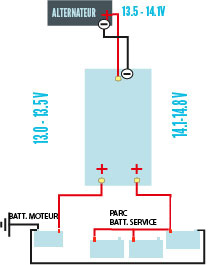

Understanding how it works : The alternator charger is connected in place of the charge distributor. At start-up, the alternator charger behaves like a distributor with specific control of the engine battery's behavior. When the engine battery has recovered its initial charge (after one or two minutes on a working installation), the alternator charger maintains the voltage on the engine battery and "tricks" the alternator into providing a maximum current which is then amplified in voltage to recharge the service batteries with an adapted charge cycle. |

|

The alternator charger is characterized by its easy installation as it simply replaces the existing distributor. It is the ideal solution for fast and complete recharging of service batteries from the alternator and one of the first options to consider for improving autonomy.

It represents an interesting alternative to the installation of a generator insofar as the alternators represent an important source of energy on board (most of the current engines have alternators whose power is higher than 100A). By optimizing the recharge from the engine (adjustment of the charge cycle), the batteries can be recharged quickly.

| Function | Fast (2 to 5 times faster) and completecharging of the service batteries from the alternator and charge distributor for the engine battery |

|---|---|

| Connection | Without disassembling the alternator (connection similar to that of a distributor) |

| Compatible alternators | All types of 12V alternators up to 300A. Several alternators can be connected to the alternator charger as long as their combined power does not exceed 300A. |

| Compatibility | Compatible with all types of batteries including lithium (9 cycles available) and alternators. |

| Charging cycle applied | IUoU three-phase charge cycle with temperature compensation |

| Charging current | 300A maximum (depends on alternator power) |

| Number of outputs | One service battery output (three-phase cycle) One motor battery output (voltage regulation) The number of service or motor outputs can be increased by using a prosplit R cascade splitter |

| Control and parameterization | Information available by LED: voltage control, battery type set, alarms. |

| Temperature sensor | Two probes included (one for the service park to adjust the charging voltage and one to ensure the protection of the alternator). |

| Remote control panel | The optional remote control panel, allows to control all the parameters of the charge cycle and to stop or restart the boost function (delivered with 10 m cable) |

| Weight | 5.0 Kg |

| Dimensions | 370*288*70 mm |

The range of alternator chargers extends in 12 V from 80 A to 400 A and in 24 V from 80 A to 200 A. You will find the whole range in the product sheet available under this link.

The charging performances obtained from the alternator become equivalent to those of the most sophisticated shore power chargers (three-phase charging cycle (boost, absorption, floating) by software control with temperature compensation of the battery park). This product is also called booster because it allows to recharge a battery pack 3 to 5 times faster than with a system based on a diode charge distributor (twice as fast as a system where the battery is connected directly to the alternator).

As an option, a remote control panel can be used which provides all the information corresponding to the charge cycle (voltage, temperature, status of the cycle) but also allows the boost function to be activated or deactivated. This control panel is available under this link

The results obtained with the alternator charger are equivalent to those of the alternator regulator, but this product differs in that it is easy to install (no need to disassemble the alternator).

|

Understanding how it works : The alternator charger is connected in place of the charge distributor. At start-up, the alternator charger behaves like a distributor with specific control of the engine battery's behavior. When the engine battery has recovered its initial charge (after one or two minutes on a working installation), the alternator charger maintains the voltage on the engine battery and "tricks" the alternator into providing a maximum current which is then amplified in voltage to recharge the service batteries with an adapted charge cycle. |

|

Sur notre blog conseil, découvrez les réalisations incluant l'installation d'un chargeur d'alternateur.